Between 2016 and 2018, our company was involved in the construction of the Lake Garda cyclepath near Limone.

This structure is part of a wider project to create a cycle route around the entire shoreline of Lake Garda, involving councils from the regions of Lombardy, Veneto and Trentino.

THE PROJECT

The works we carried out near Limone complimented the works previously carried out between the centre of the village and “Capo Reamol”, bringing the cyclepath to the boundary between Lombardy and Trentino. This section of the route was, without doubt, the most demanding part to construct in technical and practical terms, given the unique nature of the structure and its position in an environment that poses numerous morphological challenges.

The site presented a number of difficulties, from the absence of a storage area for materials and machinery, to the presence of the busy SS45bis road alongside the lake (and the requirement to guarantee the normal flow of traffic without interruptions during the works), to the specific challenges of carrying out the works in such an unusual environment.

THE WORKS

In the first phase of the works, carried out between September 2016 and May 2017, we scaled and secured the rockfaces above the new cyclepath's route. T

he teams involved in carrying out this work were made up of three or four specialist rock climber workers, trained and experienced in rope access work. A total of five teams worked on the rockface to ensure the project was delivered quickly and continuously.

Two types of structure were installed to protect against rockfall:

- rockfall barriers to ensure any rocks falling from above are contained nets anchored to the rock

- and the slopes required to prevent sections of rock from detaching from the rockface

Prior to the installation of these structures, the entire rockface was inspected and scaled to ensure safety whilst the other activities carried out.

Over around nine months, we scaled and cleaned a total of 15,000 m² of rockface, fitted 3,670 m² of rock for barriers and 14,500 m² of metal netting, as well as drilling a total of 4,200 m of holes in the rock. All materials were transported and put in position using a helicopter which, during this stage of the works, flew for just under 3,000 minutes.

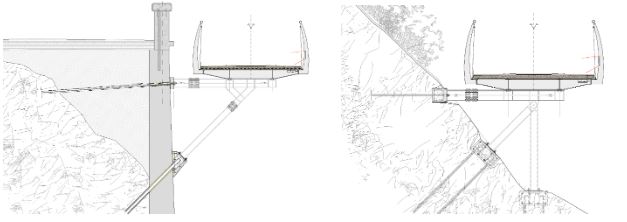

For the second and final phase of the works, carried out between May 2017 and July 2018, we were involved in the construction of the cyclepath itself. An innovative piece of engineering which befits the special and challenging surroundings. It is a made-to-measure structure, created using a construction system that involves the cantilever installation of the walkway using a series of pre-assembled 6 m long modules.

Each section of the walkway has different dimensions, in order to cope with the contours of the mountain side. The main supporting structure is longitudinal, anchored using a “double bracket” system, itself supported by anchors cemented into the rock or the roadside to a depth of between 4 and 10 m, depending on the terrain.

Example cross-section of the cantilever structure attached to the wall and the rock

Both of these types of attachment offer the advantage of having the floor of the new route detached from the wall and the rock. By being disconnected from both the linearity of the roadside and the irregularity of the rockface, the cycle path can have a more harmonious layout, with a curve radius more suited to the requirements of cyclists and pedestrians.

A number of different teams were involved in carrying out this work, depending on the specific jobs involved. As well as specialist rock climber workers, there were teams of bricklayers, drillers and electricians. The galvanised steel main structure and the floor were fitted with the assistance of a helicopter, in order to avoid disruption to traffic.

The floor is made from slabs of concrete which are finished with an imitation wood effect. The parapet, with its galvanised steel structure, features a lightweight stainless steel net. Finally, steplight lighting was installed to ensure that the cyclepath can also be used at night. In just over 13 months, we drilled holes for foundation anchors and micropiles with a total depth of 7,100 m, fitted more than 430,000 kg of steel, 3,120 m² of flooring and around 3,800 m² of parapets.

Almost all of the component parts of the walkway were transported and put in position using a helicopter which, during this stage of the works, flew for more than 4,300 minutes. Occasionally, some heavy components of the cyclepath which could not be transported by helicopter were installed at night using a mobile crane.